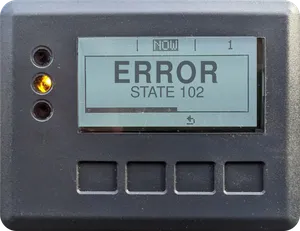

STATE 102

AC voltage too high

The inverter detected an AC voltage level at its output that exceeds the grid-compliant limit.

cl

galvo

igplus

primo

symo

Expected Behaviors

- The inverter is displaying a STATE 102 message with a red or amber LED and is not currently operating. It is testing grid conditions every 5 minutes. Once the grid values return to within the permissible range, the inverter will automatically resume feeding energy into the grid.

- During startup, the inverter checks grid voltage. This error may occur if the voltage exceeds 5% above nominal (e.g., 252V on a 240V grid). While operating, the inverter continues to monitor voltage and may trigger this error if the 10-minute average exceeds the upper threshold (e.g., 255V on a 240V grid).

State Class

A state class is a generalized description of errors, catagorized by the number the STATE code starts with.

These errors are primarily related to grid parameters and external environmental conditions. The inverter's typical response is to stop generating power to comply with grid regulations, continuously monitor the grid, and automatically restart once conditions return to normal. No internal fault is usually indicated, it's more about protection and regulatory compliance. Persistent issues may require having a professional inspect the site wiring or grid quality. In a normally operating inverter, these errors typically refer to an issue the system detected externally, but in some cases may have been caused by an internal component failure.

- In some cases, power cycling the inverter may clear the 102 error state. To do so, disconnect both the DC (solar) and AC (grid) power sources, both must be turned off to allow the inverter to discharge. Leave the system off for approximately 3 minutes, then restore AC and DC power. Once back on, the inverter will conduct a series of self-tests, then enter a startup process that will take about 5 minutes (required by code). After which, the inverter should return to normal operation.

- Power quality issues are often caused by temporary fluctuations on the grid. When the grid conditions return to normal, the inverter should automatically correct and resume feeding the grid with no further intervention.

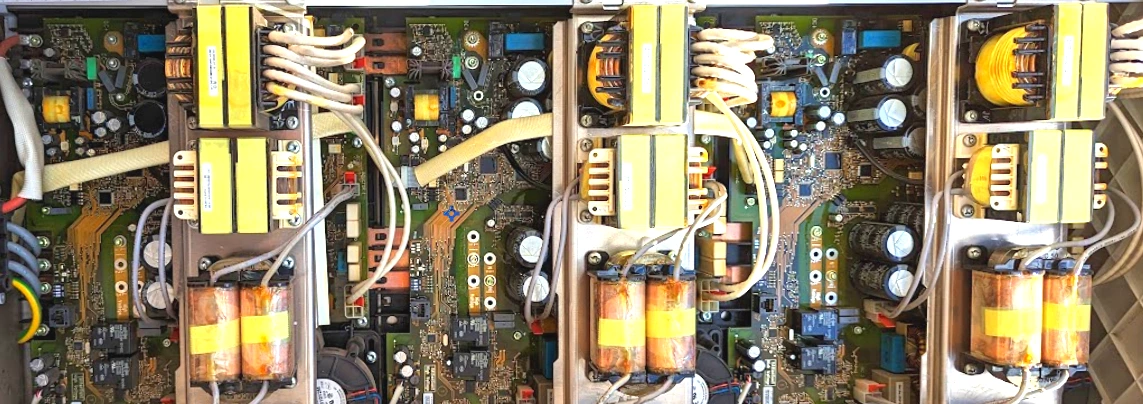

- If this issue persists, it may be that the inverter has detected a fault within the external wiring and components, or an internal failure in the inverter. Further diagnosis, such as live circuit testing and internal inspection is required to troubleshoot further, which should only be performed by a trained Fronius Service Provider. Defective components or the inverter itself may require replacement.

Tips for Qualified Persons

The following procedures involve safety risks and potential for equipment damage. They are intended only for qualified personnel trained to identify and avoid the hazards that exist, and possess the appropriate PPE. These are general tips to aid professionals in troubleshooting, not instructions or directives to perform them.

We assume no liability for injury or damage resulting from their use.

- Perform a hard power cycle by disconnecting both the DC and AC power sources allowing sufficient time for internal capacitors to fully discharge, then reconnecting both power sources to restart the inverter.

- The STATE 102 error can indicate an issue with AC power quality. Common steps to evaluate the AC line conditions include:

- Measure the AC voltage and frequency at the inverter input terminals.

- Verify terminal torque values are within specification and visually inspect for signs of damage or overheating.

- Ensure the conductor cross section is suitable for the inverter’s continuous output rating and the wiring run distance.

- Confirm that all cables, connectors, and screws on the AC board are properly seated and secure.

- Verify that the country code is correctly configured in the hidden service menu (press third button 5 times) using code 73887. For gen24 models, check and configure the country code using the Fronius Solar.start app. Even when the country code is set correctly, rerunning the country code setup can help correct corrupt data.

- Verify that the neutral conductor (or ground reference) is securely and correctly connected at both the inverter terminals and the main bonding point in the premises' electrical system. A loss of ground reference can cause voltage imbalance, improper operation, and trigger certain error states.

- High voltage at the inverter may indicate high resistance on the AC output. Compare voltage readings:

- At the inverter's AC terminals

- At the service entrance

- During inverter operation vs. when it is off

- In some regions, grid voltage or frequency may operate just outside of the inverter’s preset thresholds. If all other potential causes have been ruled out, a trained Fronius Service Provider may adjust the inverter’s grid disconnect parameters to better match local conditions. This adjustment should only be performed after confirming grid compliance and verifying that no wiring or installation issues are contributing to the behavior.

- If all inspections and diagnostics have been completed and no resolution is found, it may be necessary to replace the faulty component, or the inverter itself. For advanced troubleshooting specific to your site, or to initiate a warranty claim, contact Fronius Technical Support at 1-877-Fro-nius (1-877-376-6487).

Fronius inverters in the U.S. typically come with a standard 10-year warranty. Starting in 2024, registering the inverter on the Fronius Solar.web website (the Fronius solar monitoring platform), extended the warranty by an additional 2 years, totaling 12 years of coverage, and updates the warranty start date to the actual installation date. Fronius has also offered warranty extensions of up to 20 years.

The inverter label, typically located on the bottom of the unit, lists the device serial number. To check if your inverter is still covered, call Fronius Technical Support at 1-877-Fro-nius (1-877-376-6487)

Founded in 1945 by Günter Fronius in Pettenbach, Austria, Fronius began as a repair shop for radios and electrical equipment. Recognizing the need for efficient battery charging, Günter developed a device to recharge car batteries, marking the company's first foray into energy solutions.

The best point of contact is your original installer

If the orginal installer is no longer available, contact a local Fronius Service Provider in your area.

Fronius Technical Support can also be reached at 1-877-Fro-nius (1-877-376-6487)

DENVER RESIDENTS: Is your system located in the Denver, CO metro area? CONTACT US