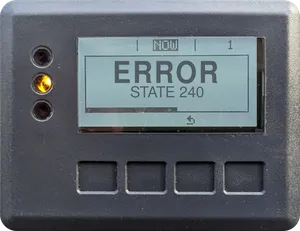

STATE 240

Arc detected

The inverter detected characteristics of an electrical arc on the DC side and triggered safety shutdown.

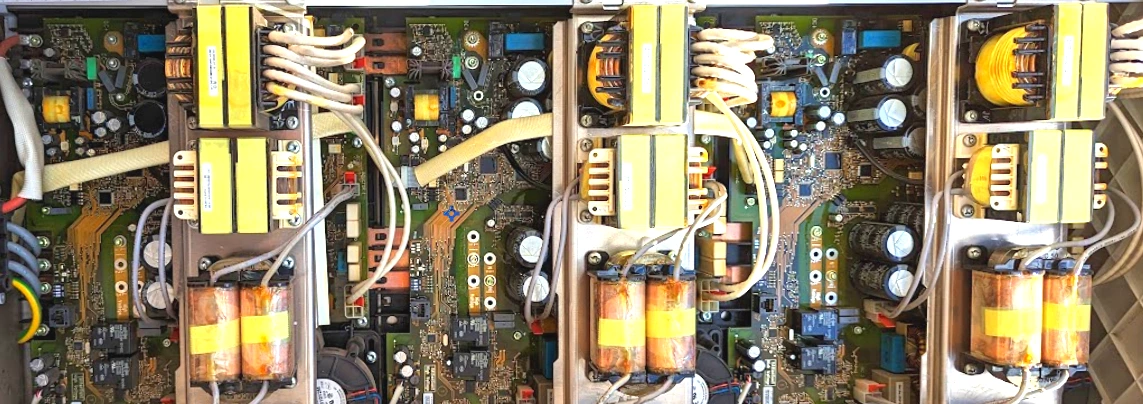

galvo

primo

symo

Expected Behaviors

- This code typically appears for 4 seconds and is immediately followed by other related status codes.

State Class

A state class is a generalized description of errors, catagorized by the number the STATE code starts with.

These errors point to internal faults in the inverter itself, such as failed sensors, faulty current/voltage readings, or communication errors between internal modules. In many cases, these errors shut down the inverter and require intervention to resolve. They may not clear automatically and often point to hardware degradation or failure. Depending on the component affected, replacement or service by a Fronius trained technician is often needed, especially if the issue recurs..

- While many arc fault detections are false positives, a true arc fault represents a potentially hazardous condition and should be addressed by a qualified professional before attempting to restart the inverter.

- In rare cases, arc fault detection may be triggered by rapidly changing sunlight across the array, such as from passing clouds or aircraft, especially in systems using older modules or noisy power electronics like optimizers.

- Ensuring that the firmware is up to date can often resolve compatibility or stability issues. If your inverter is connected to the Fronius solar.web platform, log in and under the components tab, ensure the most recent firmware is installed.

- If the inverter appears to be operating normally, press the ENTER button to acknowledge and clear the 240 error message.

Tips for Qualified Persons

The following procedures involve safety risks and potential for equipment damage. They are intended only for qualified personnel trained to identify and avoid the hazards that exist, and possess the appropriate PPE. These are general tips to aid professionals in troubleshooting, not instructions or directives to perform them.

We assume no liability for injury or damage resulting from their use.

- The arc fault detection system specifically monitors for **series arcs** in the DC circuits. Perform the following inspections:

- Check all DC connectors, especially site-made MC4 connections, for proper termination and signs of wear or arcing.

- Ensure all fuses and disconnects are properly closed and seated.

- Verify torque on all DC terminal points; re-terminate any connections that appear corroded or loose.

- Inspect internal module conductors and bypass diodes for damage or degradation.

- Rapid fluctuations in irradiance (e.g., from low-flying aircraft, fast-moving clouds, etc.) can sometimes falsely trigger arc detection, particularly in systems with aging diodes or electrically noisy MLPE devices. If confirmed as a false trigger, document the conditions and consult Fronius support if the issue persists.

- Ensure the inverter is running the most recent firmware version, and update if necessary.

- If the system inspection passes and no further issues are detected, confirm and acknowledge the 240 error state by pressing the ENTER button on the inverter display.

Fronius inverters in the U.S. typically come with a standard 10-year warranty. Starting in 2024, registering the inverter on the Fronius Solar.web website (the Fronius solar monitoring platform), extended the warranty by an additional 2 years, totaling 12 years of coverage, and updates the warranty start date to the actual installation date. Fronius has also offered warranty extensions of up to 20 years.

The inverter label, typically located on the bottom of the unit, lists the device serial number. To check if your inverter is still covered, call Fronius Technical Support at 1-877-Fro-nius (1-877-376-6487)

Founded in 1945 by Günter Fronius in Pettenbach, Austria, Fronius began as a repair shop for radios and electrical equipment. Recognizing the need for efficient battery charging, Günter developed a device to recharge car batteries, marking the company's first foray into energy solutions.

The best point of contact is your original installer

If the orginal installer is no longer available, contact a local Fronius Service Provider in your area.

Fronius Technical Support can also be reached at 1-877-Fro-nius (1-877-376-6487)

DENVER RESIDENTS: Is your system located in the Denver, CO metro area? CONTACT US