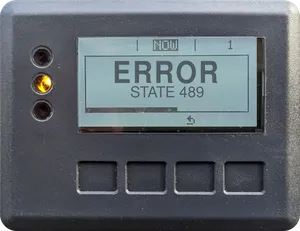

STATE 489

Permanent overvoltage at intermediate circuit capacitor

The inverter detected sustained overvoltage at the intermediate circuit capacitor causing the capacitor overvoltage protection to trip, indicating persistent energy buildup with no discharge path to the grid.

primo

symo

Expected Behaviors

- The inverter is displaying a STATE 489 message with a red or amber LED. Feed-in to the grid has been temporarily interrupted. The inverter will re-enter the startup phase and, if all self-tests pass, will resume normal operation automatically.

State Class

A state class is a generalized description of errors, catagorized by the number the STATE code starts with.

These errors typically point to internal software mismatches, startup sequence problems, or hardware module communication failures. The inverter cannot operate while a Class 4 error is active. These issues require inspection and servicing by a Fronius Trained Service Partner to avoid misconfiguration, firmware mismatches, or potential equipment damage.

- Ensuring that the firmware is up to date can often resolve compatibility or stability issues. If your inverter is connected to the Fronius solar.web platform, log in and under the components tab, ensure the most recent firmware is installed.

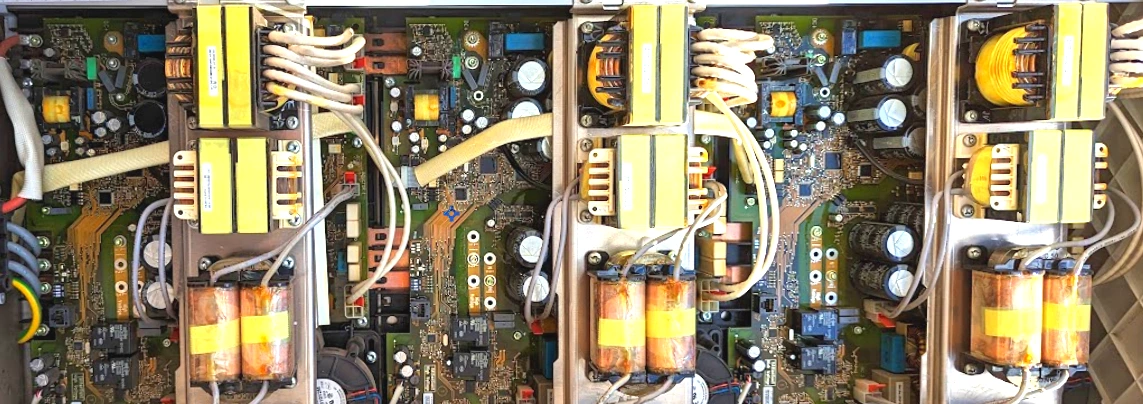

- If this issue persists, it may be that the inverter has detected a fault within the external wiring and components, or an internal failure in the inverter. Further diagnosis, such as live circuit testing and internal inspection is required to troubleshoot further, which should only be performed by a trained Fronius Service Provider. Defective components or the inverter itself may require replacement.

Tips for Qualified Persons

The following procedures involve safety risks and potential for equipment damage. They are intended only for qualified personnel trained to identify and avoid the hazards that exist, and possess the appropriate PPE. These are general tips to aid professionals in troubleshooting, not instructions or directives to perform them.

We assume no liability for injury or damage resulting from their use.

- Verify the DC voltage at the inverter's input terminals. A temporary overvoltage condition may have occurred, especially during cold weather conditions which can increase array voltage. Ensure the system's design accounts for potential temperature-induced voltage rise.

- Leakage to ground may be present when a STATE 489 is displayed, proceed with caution. Metal surfaces that are not normally energized, may be if a fault exists. Inspect the DC circuits and grounding system thoroughly:

- Isolate DC circuits and measure insulation resistance between each conductor and ground. The value should not exceed the threshold set in the inverter (typically 1 MΩ), even in damp conditions.

- Check the continuity of the ground-fault fuse and replace if needed.

- If present, ensure the GFDI board is correctly connected.

- For IG inverters, verify the jumper position on the IG CTRL board is correct.

- Confirm that array grounding is properly bonded within the inverter.

- Ensure the inverter is running the most recent firmware version, and update if necessary.

- If all inspections and diagnostics have been completed and no resolution is found, it may be necessary to replace the faulty component, or the inverter itself. For advanced troubleshooting specific to your site, or to initiate a warranty claim, contact Fronius Technical Support at 1-877-Fro-nius (1-877-376-6487).

Fronius inverters in the U.S. typically come with a standard 10-year warranty. Starting in 2024, registering the inverter on the Fronius Solar.web website (the Fronius solar monitoring platform), extended the warranty by an additional 2 years, totaling 12 years of coverage, and updates the warranty start date to the actual installation date. Fronius has also offered warranty extensions of up to 20 years.

The inverter label, typically located on the bottom of the unit, lists the device serial number. To check if your inverter is still covered, call Fronius Technical Support at 1-877-Fro-nius (1-877-376-6487)

Founded in 1945 by Günter Fronius in Pettenbach, Austria, Fronius began as a repair shop for radios and electrical equipment. Recognizing the need for efficient battery charging, Günter developed a device to recharge car batteries, marking the company's first foray into energy solutions.

The best point of contact is your original installer

If the orginal installer is no longer available, contact a local Fronius Service Provider in your area.

Fronius Technical Support can also be reached at 1-877-Fro-nius (1-877-376-6487)

DENVER RESIDENTS: Is your system located in the Denver, CO metro area? CONTACT US

Comment

Status code 479 may appear five times, one after another. Confirm state code by pressing enter button. See STATE 479